Making Fishing Hooks

Some notes on how fishing hooks are made. The main gist is that you need to balance between strength, flexibility, and brittleness. A tempering oven is needed for hook production. Gamakatsu, a leading producer of hooks, uses digitally controlled tempering to make this repeatable and precise.

Material

Most fishing hooks are made from high carbon steel wire. It’s very important for this wire to be uniform, otherwise you’ll get weak parts in your hook.

Fishing hooks are often either zinc plated (one process to accomplish this is galvanization) for corrosion resistance, or nickle-plated to give it a black, stealthy sheen.

Forming

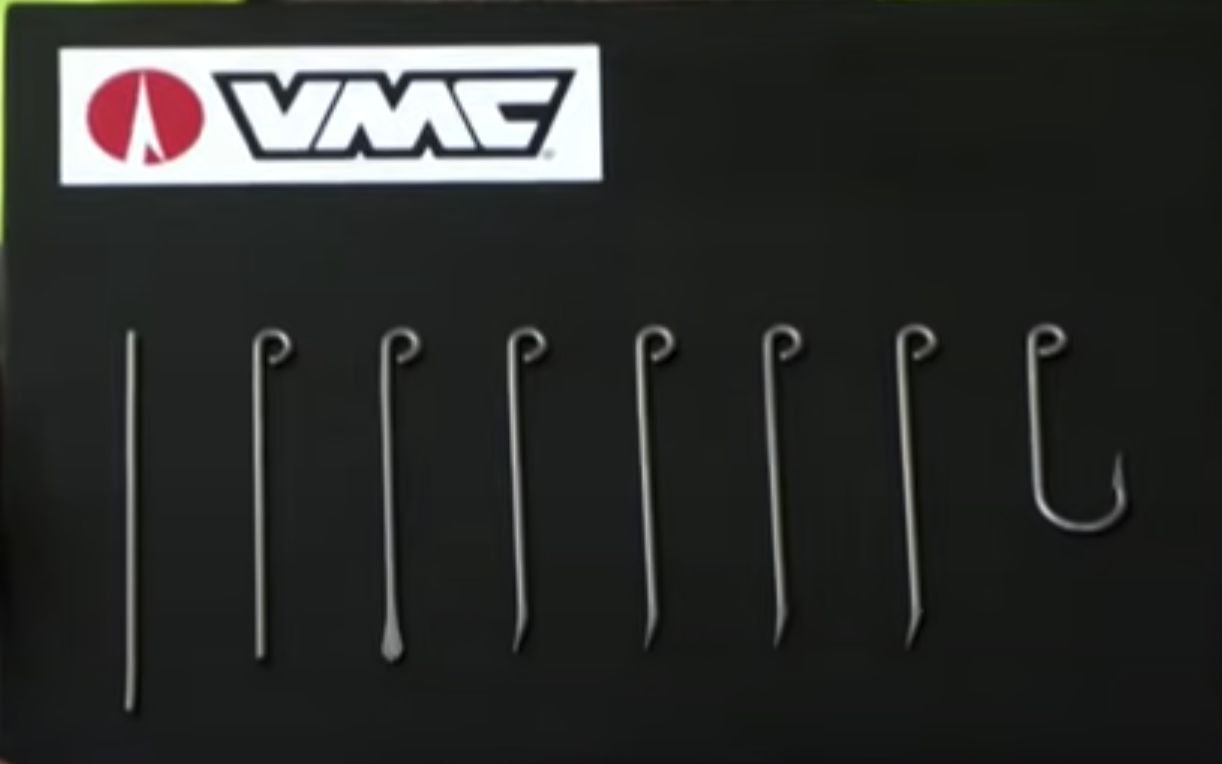

VMC uses (8) steps automated by machines:

- Cut a length of wire and strengthen it

- Add an eye by looping the top

- Forge / flatten the end

- Cut to size

- Coarse grind for sharpening

- Add barb

- Sharpening finish (while the hook is still straight!!)

- Shape the hook

Tempering

Make the metal hard

To harden the metal, you need to:

- Bring it up to a temp based on your metal type

- Hold it at that temp so that the metal is uniformly hot. How long it’s held there affects the material’s hardness.

- Cool it down (Gamakatsu cools their hooks in oil).

Make the metal less brittle

Same thing, lower temp.

- Bring the metal up to a (lower, brittleness-reducing) temp.

- Hold it there again.

- Cool it down again

Sharpening

I’m still not sure how chemical sharpening works, but mechanical sharpening is simple enough. I’ve also seen cheap hook companies apparently solder or weld the tip of the hook on after the fact? It’s unclear to me why that would help.

Appendix

- How French company VMC makes hooks https://www.youtube.com/watch?v=qzX9Uo212fg